Product Process Matrix: How It Works And How To Create One

The product process matrix is a valuable tool that can shape your product lifecycle, strategy and decision-making. It helps you understand the relationship between product variety, production volume, and suitable production processes.

Product process matrix was originally developed for physical products and manufacturing processes but is now applied to digital products and processes. It’s a dynamic framework for digital product managers because of the unique products they can create.

Following the Product-Process Matrix, you can create a solid strategy to seize opportunities, tackle challenges, and adapt to change.

In this article, you’ll explore how product process matrices are used in digital product management. You will learn the steps for creating your product-process matrix. Lastly, you will understand how it affects the development of your products and processes.

Table of Contents

- What is the Product Process Matrix?

- What are the four stages of the product process matrix?

- How to create a product process matrix in 5 steps

- How to use a product-process matrix to develop an effective product strategy

- Factors affecting product process matrix

- What are the advantages of the product process matrix?

- Align product features with customer requirements

- Helps in choosing the best product production process

- Improve production efficiency

- Helps identify opportunities

- Develop a competitive advantage

- Take a customer-focused approach

- Allocate resources efficiently

- Enhances scalability planning

- Promotes adaptation to change

- Supports strategic decision-making

- Conclusion

- Machine Learning In Finance: 12 Essential Applications

- How To Create Interactive Compliance Training For Bank Employees

- How Fintech Apps Are Using Gamification To Increase User Engagement

- Top Gamification Companies for Employee & Customer Engagement

What is the Product Process Matrix?

Also known as the Hayes-Wheelwright Matrix, this was coined in 1979 by Robert H. Hayes and Steven C. Wheelwright in the Harvard Business Review. This framework shows how products need different processes based on their product life cycle stage.

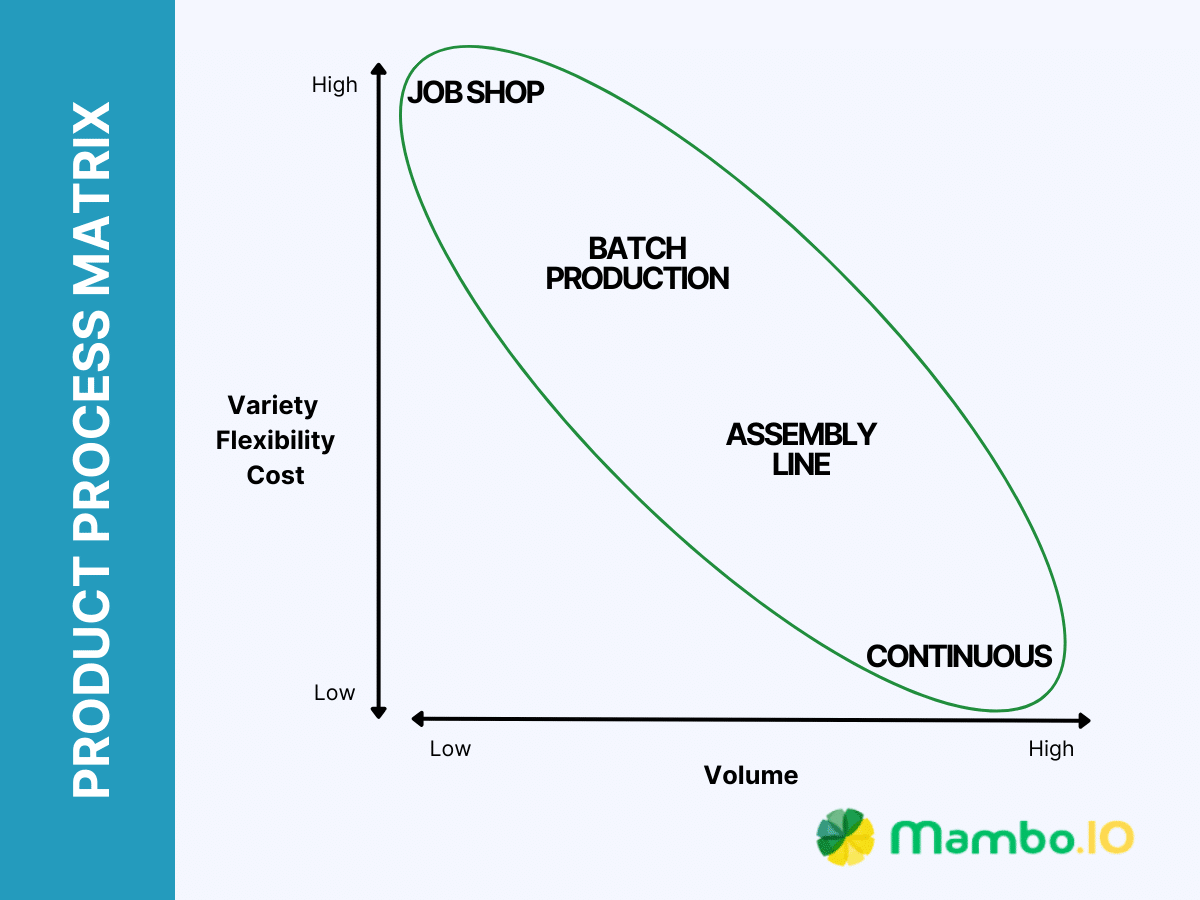

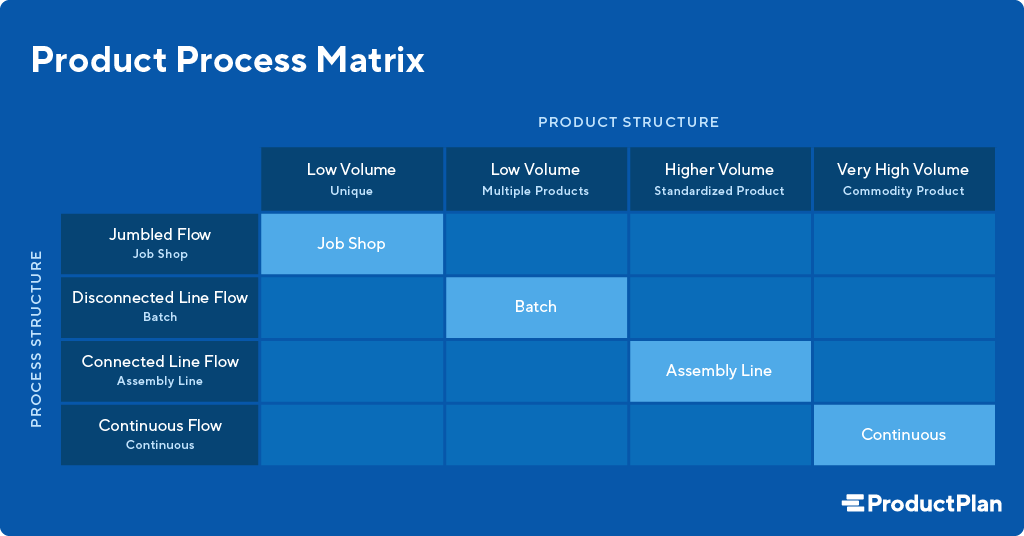

The production process life cycle has four distinct stages: job shop, batch production connected line flow, assembly line, and continuous process flow.

This matrix can be applied to produce multiple products in various industries, including manufacturing, service, and software development. It can help align production processes with product features and customer needs to find competitive advantage and market competence.

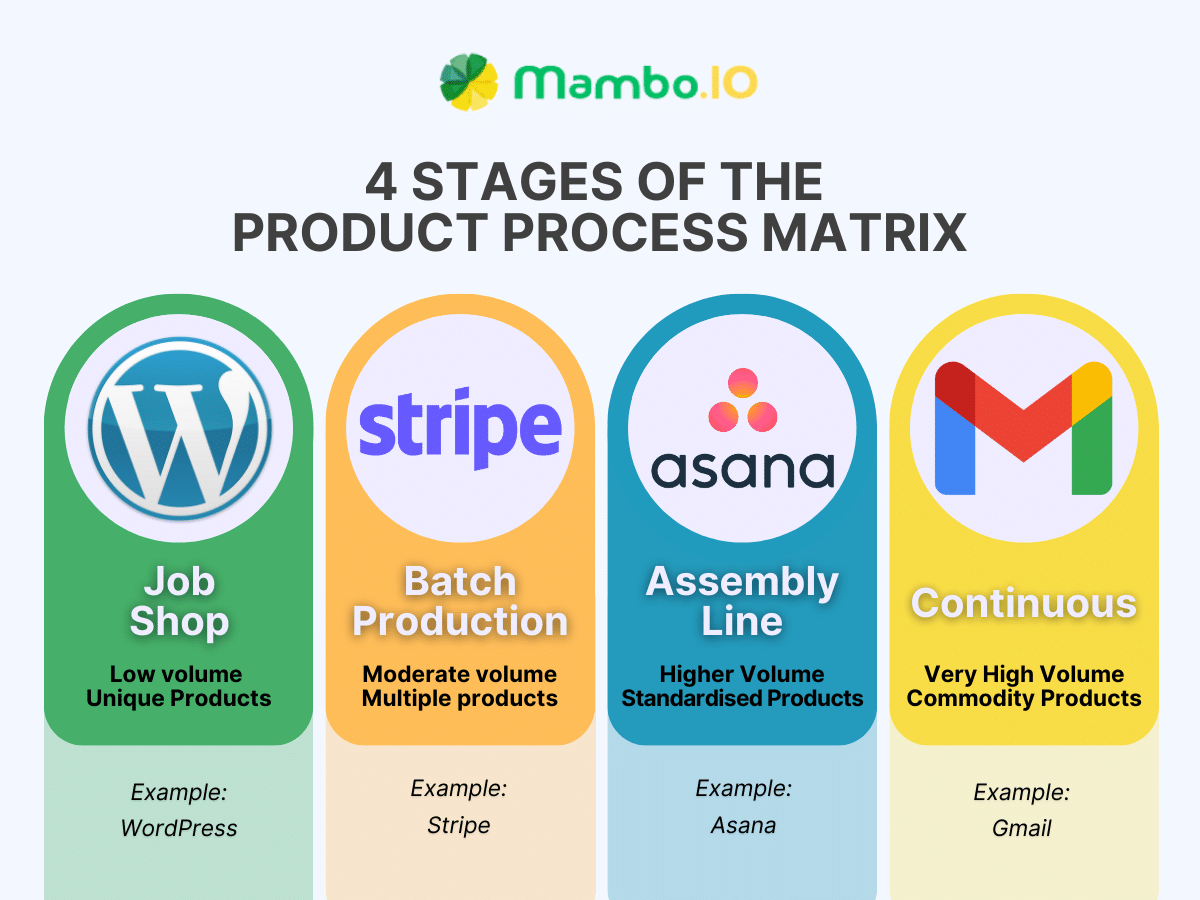

What are the four stages of the product process matrix?

The Product Process Matrix stages define four distinct production stages, each tailored to specific product characteristics. These four processes help match products with suitable digital manufacturing approaches, ensuring efficiency and customer alignment.

Source: Product Plan

#1. Job shop (jumbled flow)

In the Job Shop stage, products are individually customised for each customer. This stage is ideal for new or bespoke products with a disconnected material flow due to the specific differentiation required for different jobs.

Businesses in this category create low-volume unique products, providing personalised solutions to niche markets.

Job shop example: WordPress

WordPress is a ‘job shop’ that creates custom-designed, low-volume, highly varied websites. Each website project requires a unique combination of processes and customization to meet clients’ needs. It is the key feature of the job shop’s process structure.

Low production volume (unique products)

Each WordPress website is a custom project with unique requirements, resulting in lower production volumes.

High customization

WordPress websites require a mix of design, development, content creation, and plugin integration, making the characteristics similar to a job shop, where each job is unique.

#2. Batch process (disconnected line flow)

Batch Production makes products in moderate batches and volume, often for customised items.

The material flow is in line yet disconnected due to the unique differentiation in different batches. This stage suits businesses making similar products with moderate volumes, providing flexibility while maintaining some level of standardisation.

To produce this product, create core features that all clients share and customize to meet each client’s specific needs.

Batch process example: Stripe

Much like Stripe’s approach, a financial services company provides a standardized suite of payment solutions to different businesses. Stripe’s financial solution is designed with specific core features while offering a customised payment feature across everything they offer.

Moderate production volume

Stripe provides standardized services to improve efficiency in handling high transaction volumes. It processes transactions and offers financial services in batches instead of individually.

Moderate product variety (multiple products)

Stripe offers a range of payment processing and financial services, including online payments, subscription billing, and fraud prevention. While some customization is available, the core processes are consistent across all customers.

Batch production allows companies to optimize their operations for handling larger volumes in moderate production. It can scale and customize features to accommodate more customers and transactions without major process modifications.

Stripe’s efficient handling of high transaction volumes and moderate customization align with batch operations and production processes. While some services can be customized, core processes remain consistent for many customers and transactions.

#3. Assembly line process (connected line flow)

When demand for a product reaches high volumes or levels, the connected line process becomes an efficient choice. Often referred to as mass production, this stage features standardised, repetitive tasks that labourers perform continuously.

This approach optimises efficiency, making it suitable for higher volume and high-demand products.

Assembly process example: Asana

Asana is a project management software that allows teams to organize their work, track tasks, and collaborate on projects. It can be seen as a digital equivalent of an assembly line, where each task in a project follows a standardized workflow.

Asana breaks tasks into subtasks and checklists. You can work on them simultaneously with different team members through parallel collaboration.

Higher volume (standardized product)

Asana allows team members to be assigned tasks that align with their skills or roles. It creates a virtual division of labour in project management. It also enhances project efficiency by allowing team members to collaborate on different tasks simultaneously.

Higher volume (high-demand products)

Asana provides tools for task tracking, collaboration, and automation to improve efficiency and help teams maintain consistency in project workflows. In Asana, tasks can have dependencies, requiring the completion of one task before starting another. This creates a similar sequential work progression to an assembly line.

The process with Asana is efficient and consistent. It produces a high volume of products by quickly and consistently performing each task. The standardized workflows, task division, sequential progression, and digital efficiency are similar to the assembly line process.

#4. Continuous (continuous flow)

The Continuous Flow stage excels in high-volume, standardised production and batch processes. This approach often provides a competitive advantage through economies of scale. Products move through manufacturing with minimal human intervention, leveraging a capital-intensive setup to match demand.

Continuous flow example: Gmail

Gmail is Google’s email service for sending, receiving, and managing emails through a standardized, automated, and scalable process. The continuous flow of emails being sent, received, and processed highlights the high production volume characteristic of a continuous flow process.

Very high volume (commodity product)

Gmail handles billions of emails daily. It lets users send, receive, and manage emails with different content, attachments, and purposes on various subjects. The continuous flow of emails demonstrates the high production volume characteristic of an ongoing flow process.

Very high volume (standardised process)

Emails vary greatly in content and purpose, but sending, receiving, and managing them is always the same. Regardless of the email’s content and recipients, the same basic actions are performed.

Gmail automates most email processes, minimizing manual intervention. Users depend on Gmail’s automation to organize their inboxes, mark important emails, and manage spam.

It also has a continuous flow of incoming and outgoing emails, making it highly scalable to accommodate fluctuations in demand.

Although it doesn’t involve physical manufacturing, the continuous flow processes of digital communication share similarities with continuous flow process used in the Product-Process Matrix.

The Product Process Matrix offers a strategic compass for selecting the appropriate production stage for their products.

Companies can optimise resource allocation by aligning the product’s unique characteristics with the right production approach. They can meet customer demands effectively and gain a competitive edge.

Each stage brings advantages, making the matrix a powerful tool for intelligent production strategy, even in the digital landscape.

How to create a product process matrix in 5 steps

Creating a product-process matrix can help you analyse your current production processes and identify areas for improvement or innovation.

A product-process matrix for digital products categorises based on product variety and product volume to determine the appropriate production process.

A software development company can use the Product-Process Matrix to determine the best development approach for its software products. This is based on factors such as product complexity and production volume.

To understand how to use it for a software company, here’s how to create a product-process matrix in five steps:

#1. Define the product variety

Defining how flexible and adaptable your product will be is essential. This involves pondering over aspects like product features, its inherent quality, and the price tag attached.

Determine your product’s range of variations or customisations. Then, define clear categories for product variety. Categories could range from “High Variety” to “Low Variety.”

A product of High Variety offers extensive customisation options, while a “Low Variety product” has standardised features with little customisation.

How to define and categorise product variety:

- Definition: The software company assesses the complexity of its software products. It considers factors such as the number of features, integrations, user interfaces, and customizations.

- Categorization: Based on the complexity assessment, the software company can classify their products into high, medium, or low complexity categories.

#2. Evaluate demand and production volume

Assess the demand for your digital products and the production volume needed to fulfil those demands. Use historical data, forecasts, and market research to estimate sales and orders.

Understanding the trends in your market segment, estimate the production volume for your digital product. Then, designate production volume categories based on the estimated volume. Use categories to plan production effectively.

How to evaluate demand and categorise production volume

- Evaluation: The company can estimate production volume or user interaction with different metrics. It can be measured by software licenses, downloads, active users, or usage frequency.

- Categorization: Similar to product variety, they categorise the production volume as low, moderate, or high.

#3. Plot your digital product

Utilise a spreadsheet, a dedicated software tool, or a paper template to construct your product process matrix. Place product variety horizontally and product volume vertically.

- Product variety axis (horizontal): Categorise digital products based on their level of customization on the product variety axis. Are they highly customizable or standardised?

- Production volume axis (vertical): Place the digital product on the production volume axis based on the estimated volume. Is it targeting a small, niche audience or a broad user base?

How to plot products on the matrix

- Matrix Creation: The software company creates the ‘product variety categories’ along the horizontal and the ‘production volume’ along the vertical axis.

- Product Plotting: The software company plots its products on the matrix based on their complexity and volume. Highly complex products with low volumes may be placed in a different matrix quadrant. On the other hand, products that have low complexity but high volume are in the opposite quadrant.

You can use colours, symbols, or numbers to indicate the degree of fit between each customization and production volume to enhance clarity.

#4. Identify the appropriate process

Determine which quadrant it falls into based on where your digital product is plotted on the matrix. Each quadrant corresponds to a different production process: job shop stage, batch, line (assembly line), or continuous flow.

Start listing everything involved in the production of your product based on the quadrant you have identified.

These may be primary activities, resources, and valuable inputs and outputs necessary for procuring and producing the products.

Visualise these processes using techniques like process mapping, flowcharts, or diagrams. Look at how you create your product to spot any issues or room for improvement.

How to determine the appropriate development approach

The company identifies the quadrant in which each product falls and matches it with a suitable development approach. The software company can choose suitable practices, methods, and tools.

- Job Shop: These are high-complexity, low-volume products that require customization for each customer. Adaptive and custom development tools may better suit the ‘job shop process’.

- Batch Production: These products have moderate complexity, moderate volume, and some customization options. Batch products use agile or iterative methods to combine custom and standardized components.

- Assembly Line: refers to the production of lower complexity, high volume products that can be standardized to some extent. This process could benefit from Agile or Scrum methodologies.

- Continuous Flow: This method is suitable for low-complexity, high-volume products that can be highly standardised and automated. It often prioritises automation testing, continuous integration, and lean development practices.

#5. Evaluate and refine.

Continuously review the matrix. Consider whether the production process recommended by the matrix aligns well with your digital product’s nature, goals, and constraints.

Ensure its reliability by iterating and updating it regularly based on further insights or changes in product direction. Refine your analysis as you gather more information.

How to evaluate and refine the matrix

The software company regularly assesses how its products fit into its product development process and approaches. They can validate it with actual data, feedback, or analysis. Then, evaluate the chosen process’s feasibility, efficiency, and scalability.

They can review the matrix to ensure their practices match their products as they change due to market shifts or customer demands.

Consider these practical applications for a software company when evaluating and refining the matric:

- Focus on core products: Focus on a core product category like web applications. Evaluate your competitive advantage and leverage your job shop’s production process.

- Optimise batch production: Improve the efficiency of your batch production process for mobile applications by reducing inventory levels and introducing automation.

- Innovate assembly line: Explore innovation opportunities for desktop applications’ assembly line production process by introducing modular design and customisable options.

These steps and the matrix can help businesses make informed decisions, improve continuously, and align production with product strategy and customer needs.

How to use a product-process matrix to develop an effective product strategy

A product strategy is like a map showing where your product is going. It tells you what your product is, who it’s for, and what makes it unique. It helps you ensure your product fits in with your business plan, what your customers want, and what’s happening in the market.

This is where the product-process matrix provides a framework for analysing current and potential products and their processes.

It’s a powerful tool that can help you answer critical questions about your business:

- Strengths and weaknesses of existing products and processes.

- Opportunities and threats in the external environment.

- Gaps and overlaps in the product portfolio.

- Trade-offs and synergies between products and processes.

- Industry best practices and benchmarks.

The product-process matrix identifies strengths and competitive advantages and highlights areas for improvement and innovation.

With these insights, a robust product strategy can be formulated, including a vision, goals, objectives, and a roadmap.

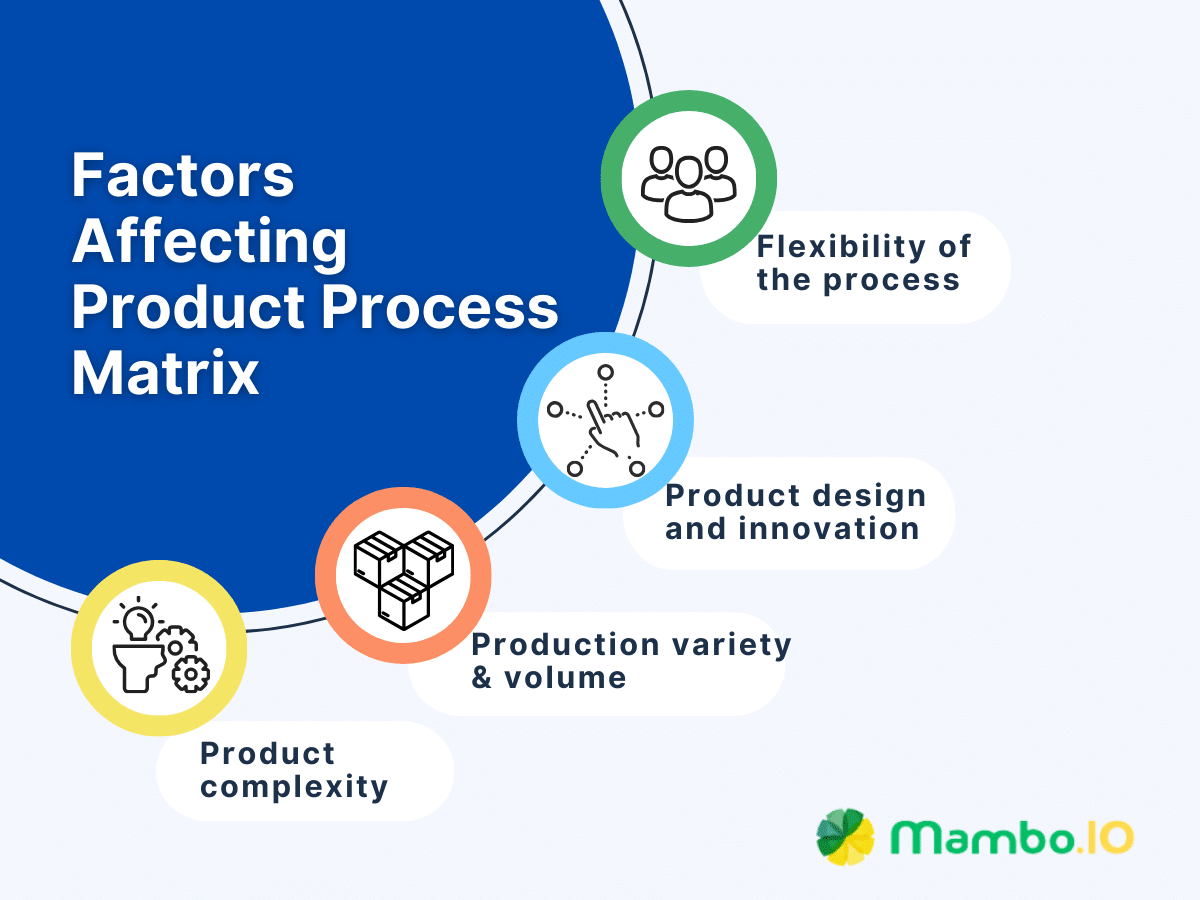

Factors affecting product process matrix

The product process matrix is not fixed; it’s adaptable and changes due to different factors. These elements hold significance as they impact the product’s attributes and production methods.

Several crucial factors are at play in this process, each influencing the overall framework.

The product process matrix is a helpful tool to help you make important decisions about your business. By adapting to changes in customer demand, you can improve your entire production process and meet market and customer needs.

Product complexity

Digital products are placed in the high customization quadrant if they require high flexibility and specific features. If a company decides to add more options and features to their products, this would require changes.

To succeed, software companies need to invest in research and create flexible and easy-to-use products. This may include user testing, market analysis, and collaboration with industry experts to identify emerging technologies and design best practices.

Product variety and volume

Offering many different products impacts the matrix. They may have to change how things are made to handle the variety. They might need to switch from making things in a fixed order (assembly line) to a flexible way (batch production).

The number of products a company makes in a specific time also matters. It affects efficiency and product quality.

When there’s a sudden rush for a product, a company might need to change how they make it. They could go from creating small batches to a smoother, faster process, like an assembly line.

However, if they need to make fewer items, they might concentrate on quality, taking a slower, more meticulous approach. This can help ensure the products meet the desired standards and satisfy customer needs.

Product design and innovation

Product design can change the whole matrix market manufacturing process. For automation and technological innovation, changes in the process may be necessary.

The level of automation impacts the product’s position on the matrix. Quadrants I and II are associated with high automation, while Quadrants III and IV lean towards more customised and complex processes.

This could also involve transitioning from standard methods, such as assembly lines, to more flexible approaches like batch production, which allows for customization.

Conversely, if the goal is product standardisation, it will change the overall digital manufacturing and process structure. They might move from flexible production (batch production system) to a structured process (assembly line) or optimise the product development process.

Flexibility of the Process

Flexible processes are key to placing digital products in the Product-Process Matrix. Those that can adapt to changes and updates without disruption are in Quadrant I or IV.

These products are versatile enough to meet various customer preferences and adapt to market or technology changes.

On the other hand, products with more structured processes are usually placed in Quadrant II or III. These products have specific features and functionalities that require a standardised and structured approach.

The product process matrix changes due to product complexity, product variety, production volume, product design, innovation, and the process. By monitoring these factors and adjusting when needed, businesses can navigate the complex world of production. They can be efficient, cost-effective, maintain quality, and exceed customer expectations.

Digital product placement in the matrix changes with technologies, customer preferences, and market conditions. Adapting the matrix to the unique features of digital products and processes is important.

What are the advantages of the product process matrix?

The product process matrix is a valuable tool that provides several advantages for product managers and business owners. Some of the benefits of the product process matrix are:

-

Align product features with customer requirements

It can align product features and customer requirements with production processes for digital products. This alignment ensures that what’s made matches what the customers desire.

-

Helps in choosing the best product production process

The matrix aids in determining the ideal production strategy for every product category and stage within the product life cycle. This means selecting the best method for producing each product, depending on its current position.

-

Improve production efficiency

Categorising digital products into quadrants allows companies to allocate resources effectively. It elevates the production procedures’ efficiency, quality, and overall satisfaction. This results in superior products and happier customers.

-

Helps identify opportunities

It enables organisations to identify opportunities for automation, streamline processes, and reduce waste in digital product production. It promotes the advancement and differentiation of the products. This ensures that products stand out and bring innovative value to the market.

-

Develop a competitive advantage

The process matrix helps evaluate the company’s competitive advantage and distinctive competence within the market. This is essential for understanding how the company’s operation fares compared to others.

Knowing how much they can customise and produce digitally can help companies identify their unique selling points and competitive advantages.

-

Take a customer-focused approach

It supports the planning and management of the product portfolio and production resources. The product process matrix understanding promotes a customer-focused approach for highly customised digital products that meet their needs.

-

Allocate resources efficiently

It helps in allocating resources efficiently to optimise costs while maintaining high-quality standards. The matrix helps plan for growth in digital products by identifying the best process strategies to prepare for increased demand while maintaining quality.

-

Enhances scalability planning

Facilitates scalability planning by anticipating future growth and preparing for it through strategic investments in production capacity. Companies can assess the risks of digital products by analysing the matrix.

-

Promotes adaptation to change

The matrix promotes continuous improvement; companies can identify areas for optimisation and improvement. It promotes adaptation to change by continuously monitoring market trends and customer needs and adjusting production processes accordingly.

-

Supports strategic decision-making

Enables customer segmentation by understanding different customer needs and tailoring products and services accordingly. This supports strategic decision-making by providing data-driven insights into production performance, market trends, and customer needs.

The product process matrix helps product managers make smart decisions and create solutions that benefit customers and stakeholders. By leveraging this tool, they can make strategic solutions that foster success and stay ahead in the ever-evolving business landscape.

Conclusion

The product process matrix is a tool originally created for the manufacturing industry. However, with the shift towards digital products, it has been adapted to fit the needs of the digital world.

It considers factors such as volume and variety of production, degree of flexibility, and the level of automation required.

The product process matrix can help you create better products faster and easier.

Whether you are a small business or a large corporation, Mambo can tailor gamification to your specific needs. Don’t miss this opportunity to transform your business with Mambo. Request a demo today and see the difference for yourself.

Download your free

“Gamification Guide”

Get your PDF now and start transforming your approach to digital engagement!

Latest Posts

Machine Learning In Finance: 12 Essential Applications

The impact of machine learning on finance is significant. Thanks to this technology, financial institutions are now equipped to make efficient decisions. Through the analysis of data sets, machine learning […]

How To Create Interactive Compliance Training For Bank Employees

Banking compliance training isn’t just another task. It’s the stage where everything else performs. Banks must navigate a myriad of regulations and laws. After all, this is a trust-driven, high-stakes […]

How Fintech Apps Are Using Gamification To Increase User Engagement

Discover how gamification in fintech is revolutionizing financial engagement, making banking fun & boosting user loyalty.