Quality Function Deployment: Phases, Tool, And Techniques

Quality function deployment, or QFD, is a method used to track customers’ needs and preferences for a product. This customer-driven engineering is used for product changes or updates, ensuring increased customer satisfaction.

This tool uses several matrices to create a customer-centred approach to deploying new or updated products. Moreover, this ensures that your customers stay using your product and that non-customers are encouraged to try it.

Understand the quality function deployment and how to use it effectively here.

Table of Contents

- What is quality function deployment (QFD)?

- Key components of QFD

- What are the four phases of quality function deployment?

- How to create a successful QDF process in 6 steps

- Tools and techniques used in Quality Function Deployment

- Examples of successful implementation of Quality Function Deployment Process

- Benefits of Quality Function Deployment

- What are the limitations of quality function deployment?

- Conclusion

- Machine Learning In Finance: 12 Essential Applications

- How To Create Interactive Compliance Training For Bank Employees

- How Fintech Apps Are Using Gamification To Increase User Engagement

- Top Gamification Companies for Employee & Customer Engagement

What is quality function deployment (QFD)?

Yoji Akai and Shigeru Mizuno invented the quality function deployment methodology in 1972. The two designed the QFD process to produce an oil tanker for a shipyard in Japan by first analysing customer satisfaction.

Before Akai and Mizuno created the quality function deployment, process quality control only involved fixing issues when they occurred. In simple terms, the quality function deployment process considers customers’ desires during product and process development. It prioritises the voice of the customer and uses a structured approach to designing products.

What is the main goal of quality function deployment?

Quality product deployment is made and used for one central aim, to design and develop a product customers will buy. However, some people often mistake what customers think they want for what they need. This is because translating customer desires can often be complex.

For instance, when selling templates online, your users may say they want the elements to have different colours. But what they may mean is that they want to be able to customise the template’s colours. And so, understanding what your customers prefer and using it for product and process design is vital.

If not, the QFD will fail to serve its purpose in securing your target market.

Key components of QFD

Here are the main components of the quality function deployment that you must know to measure and interpret customer requirements:

Product Planning Matrix: House of Quality (HOQ)

The House of Quality matrix helps ensure your customer requirements become the foundation of your product features and specifications. It derives its name from the house-like shape of the matrix. It comprises a roof and body, which you can use to separate your customers’ desires from the technical requirements.

It is one of the main elements of the QFD process and usually includes the following:

- Customer requirements

- Technical requirements

- Importance ratings

- Correlation matrix

- Competitive analysis

- Target values

The HOQ includes all the components you need to incorporate customer feedback. That’s why it’s a helpful tool for increasing product revenue.

Voice of the Customer (VOC)

The voice of the customer programme ensures that brands produce products on par with their customers’ needs and expectations. It is your customers’ feedback about your product.

It usually emphasises the needs and improvements your customers want from your product so you can develop a better service. It is also where you can see complaints and issues about your product.

How to run an effective VOC programme to collect the feedback needed for your Quality Function Deployment?

Every business should focus on the customer’s voice before releasing a product. Because of this, product managers must find a suitable and effective VOC programme to succeed in marketing their products.

Here are the different ways to collect the ‘voice of the customer and employ it for your quality function deployment:

#1. Observations

This is the most subjective way to collect your customer’s preferences and satisfaction with your product. Although it can be opinionated, you can still run your ‘voice of the customer’ programme this way. Just remember to conduct other VOC techniques for clarification after.

You can have your team or employees observe the customers when they buy your product online. Then, record how they interact with your website, page, or app after buying an item. This will tell you how satisfied they are with the product, which you can use as a basis later on.

#2. Online surveys

This is the easiest way to collect your customer satisfaction rating and preferences. You can use several sites for this for free, like Google Forms and Microsoft Forms. If you want a more customisable site for your surveys, Typeform, Paperform, and Toluna are some of the few options. These websites allow you to design survey forms with your branding.

You can also post it on your product accounts or pages. An online survey is one of the most common ways to collect detailed customer feedback.

However, one challenge is getting customers to answer your survey. So, use gamified surveys to increase your survey’s participation and engagement rate. This would give your customers a fun time as they answer a gamified survey with displayed progress bars.

For this, you can use Mambo to integrate gamification into your online surveys.

#3. In-person interviews

Unlike surveys, interviews provide more clarity about customers’ preferences and complaints. Conducting interviews means that you can ask follow-up questions to explore more of your customer’s opinions about your product. However, collecting a large amount of customer feedback for this will also take time.

#4. Social media listening

Because of the advancement of technology, people can share their opinions about products online. So be on the lookout for this because word of mouth dramatically influences how people receive your product.

#5. Focus groups

You can get several customers and group them to collect data simultaneously. This technique is similar to conducting interviews, except you’re asking questions of a group, not just an individual. Here, you can explore your customers’ experiences and issues with your product.

#6. Reviews

Most potential product buyers read the reviews before they buy them. Reviews typically consist of your customers’ product satisfaction ratings and customer service. Products sold online usually include reviews on their pages and websites.

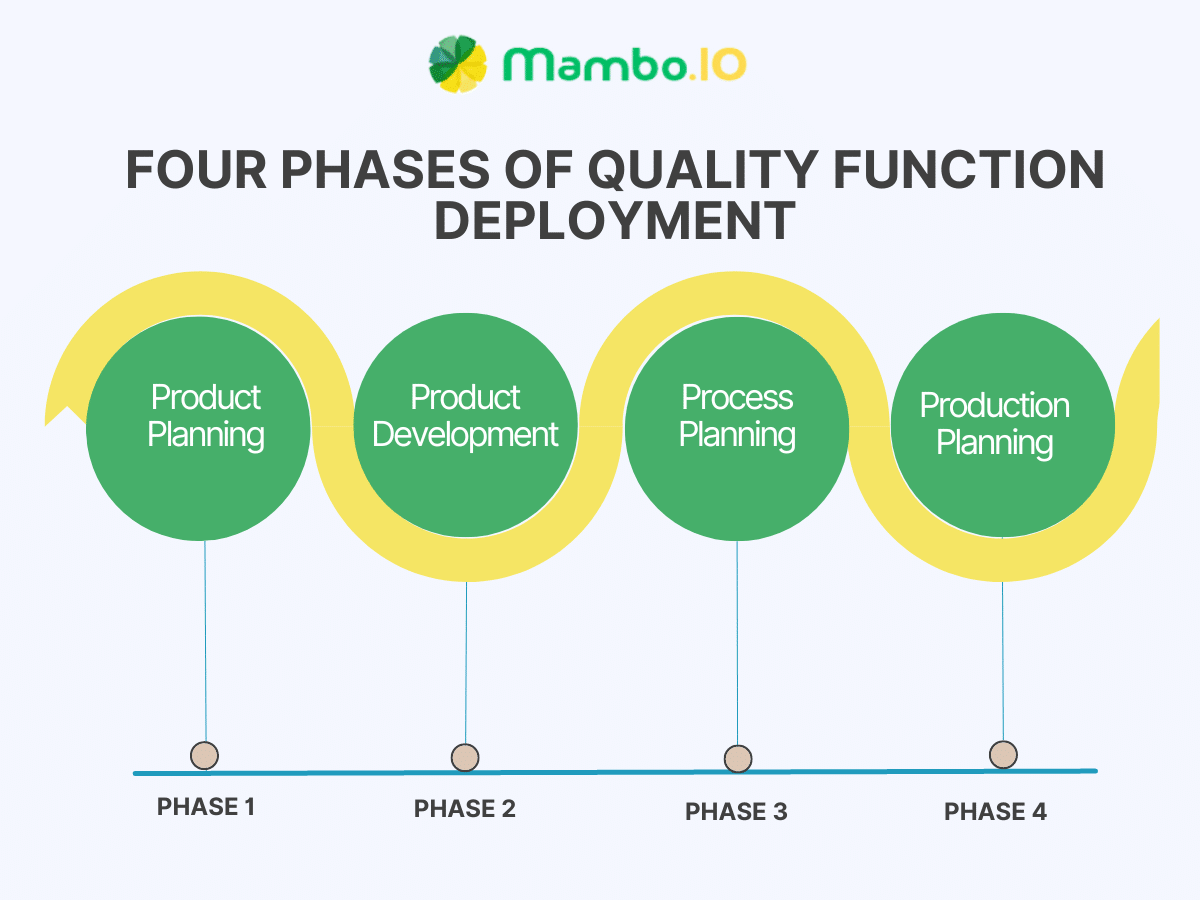

What are the four phases of quality function deployment?

Quality function deployment is a process that can be changed according to your business or product. There are different ways or phases to approach it depending on your preferences as a product manager.

Phase #1. Product planning

Collecting the voice of the customer (VOC) through surveys, interviews, or other techniques is the first step to product planning. You cannot directly design and develop a product without doing this. Moreover, you must identify your technical requirements and conduct a competitive analysis to compare your products.

In this phase, you need to know which important preferences are similar to most of your customers.

Phase #2. Product development process

Here, you should find common ground between your customer’s feedback or the VOC and the technical requirements you found. This is where you can identify which features you must improve and which specifications you must add. In this phase, you can use the house of quality as your basis.

Ensure that your customers’ preferences are included during the product development process. While doing so, remember your brand’s signature styles so you don’t lose customers who buy your products for them.

Phase #3. Process planning

After identifying what features or updates your product needs, you can start planning how to build them. Don’t skip this phase, so your product’s quality and production process aren’t affected. Here, you can decide how your product will be manufactured and its assembly processes.

Phase #4. Production planning

This quality function deployment phase is where you must identify your product’s quality control while the production process is ongoing. You can also conduct repeated prototype testing or trials for your new product to know what needs improvement.

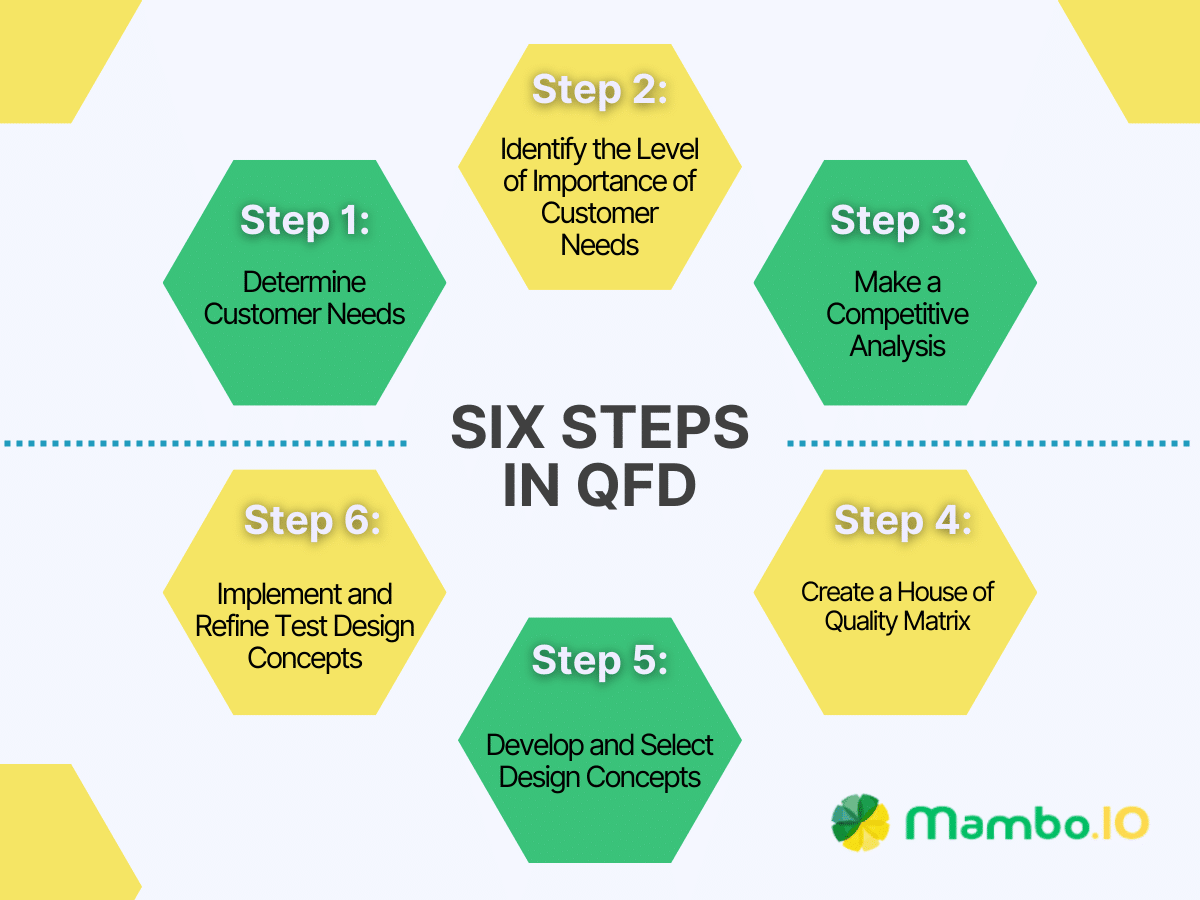

How to create a successful QDF process in 6 steps

Incorporating quality function deployment into your product development process might seem hard because of the many matrices it includes.

Here’s a guide to make it simpler for you:

Step 1: Determine customer needs (Voice of the Customer)

The initial step of the quality function deployment always focuses on your product’s customer requirements. You must gather enough information from your customers, users, or stakeholders. Doing this will help you understand their needs and expectations.

For this step, use different techniques to gather the voice of the customer. It can be through customer surveys, interviews, focus groups, market research, and more.

Step 2: Identify the level of importance of customer needs

This step is done while you collect the voice of the customer or their preferences. While you’re gathering data in a survey or focus group, have your customers rate how important their concerns are. This is usually done on a scale of one to five.

Step 3: Make a competitor’s analysis

After gathering the customer’s needs, analyse how your competitors address similar preferences. To do this, ensure you have listed all your customers’ concerns. Then, determine your competitors’ features or engineering characteristics to address these issues. Doing this will help you identify how to transform qualitative user demands into design features.

Step 4: Create a House of Quality Matrix (HOQ):

After collecting your brand’s customer requirements, you can create a house of quality. The HOQ helps you understand your new product’s goals and features by visually representing your customer’s needs and technical specifications.

Source: asq.org

As a guide, here’s what the House of Quality matrix must include:

Customer requirements (CRs)

You can get this after you have conducted surveys or used other techniques to get the voice of the customer. This is the list of your product’s customer feedback, summarising the product’s new features customers expect.

This is one of your brand’s biggest priorities. When this is not met, customers may not buy your product anymore.

This will then go to the left of the ‘house of quality’ matrix.

Technical requirements (TRs):

After identifying your product’s customer requirements, list the specific technical features that will help address them. This part addresses each customer’s needs and transforms them into a product and component specification.

Here, you and your design team should collaborate so you can identify what product specifications are needed.

The technical specifications are put on top of the house of quality, just under the roof.

Importance ratings

After you list down all of your brand’s customer desires, rate them one by one by their level of importance. Measure this using a scale of one to five. One being the highest and five being the lowest. This rating will then help you identify the areas you should focus on.

Calculate the level of importance of each of your customer’s needs and technical requirements by rating them. Then, divide each rating by the sum of all the ratings. After solving each of them, arrange them in the ‘house of quality’ matrix by their level of importance.

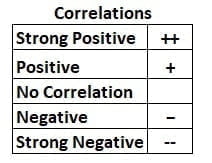

Correlation matrix

The correlation matrix identifies whether the technical requirements of the HOF affect each other. To make the correlation matrix, mark whether a technical requirement should be increased or decreased based on your customer’s needs.

Put up or down arrows above the specifications depending on whether a specification should be higher or lower.

After placing up and down arrows on the technical specifications, use the square on the roof of the HOF. Here you will put plus or minus symbols depending on how each specification affects the other.

Source: Sixsigmaguide

Relationship matrix

Identify how the customer’s needs and the technical requirements interrelate after you finish listing them. Doing this will help you identify which product specifications are needed to address customer needs and technical requirements.

To do this, determine whether the rating of the customer and technical requirements is strong, medium, weak, or none. Use the plus or minus symbol to translate these rating interpretations.

The relationship matrix is placed to the right of the customer’s needs and below the technical requirements’ importance ratings.

Competitive analysis

Competitive benchmarking is part of the HOF, where you rank where your competitor falls on your customer’s requirements. Although it will not affect your customer preference’s overall rating, it will give you an idea of your target values.

This is found on the right side of the house of quality.

Target values

Set a specific benchmark or performance target for each of your house of quality’s technical features. The target values would depend on you and your team’s decisions. You can base them on your company’s or product’s records, competitive analysis, or product experiments.

Step 5: Develop and select design concepts

You can create several design concepts based on the house of quality you made and the technical requirements listed. Ensure that important product and component specifications are included in your designs.

In this step, brainstorm design ideas and concepts with your development team. Then, make a detailed analysis of each design to choose which addresses your brand’s customer needs best.

Step 6: Implement and refine test design concepts

After you carefully select a product design, make prototypes of models based on it. Then, you can also have customers test it so you can identify what should be improved. Do this by collecting feedback from the testing process.

If areas need improvement in your design based on the testing, refine your product. Lastly, monitor customer feedback and market trends to see if your product remains aligned with them over time.

Tools and techniques used in Quality Function Deployment

Quality function deployment is essential to ensuring an increase in customer satisfaction ratings. But QFD includes more than one technique or tool. Instead, you can use several tools to provide a structured process for incorporating customer feedback into your product.

Here are several tools you can use to implement quality function deployment:

House of Quality

The House of Quality is the most popular tool for quality function deployment. When making one, ensure your customer’s needs, technical requirements, and competitive analysis are ready.

Additionally, remember to ensure that the words you use for the HOF are short and easy to understand. You will present this to your development team, so your customer’s needs and the technical specifications should be easily understood.

House of Quality Template

Creating your own house of the quality template will take time. There are ready-made ‘house of quality’ templates for you online. You can use it to successfully control product quality without spending too much time.

Watch the video below to help you plot your own House of Quality matrix!

Source: Youtube

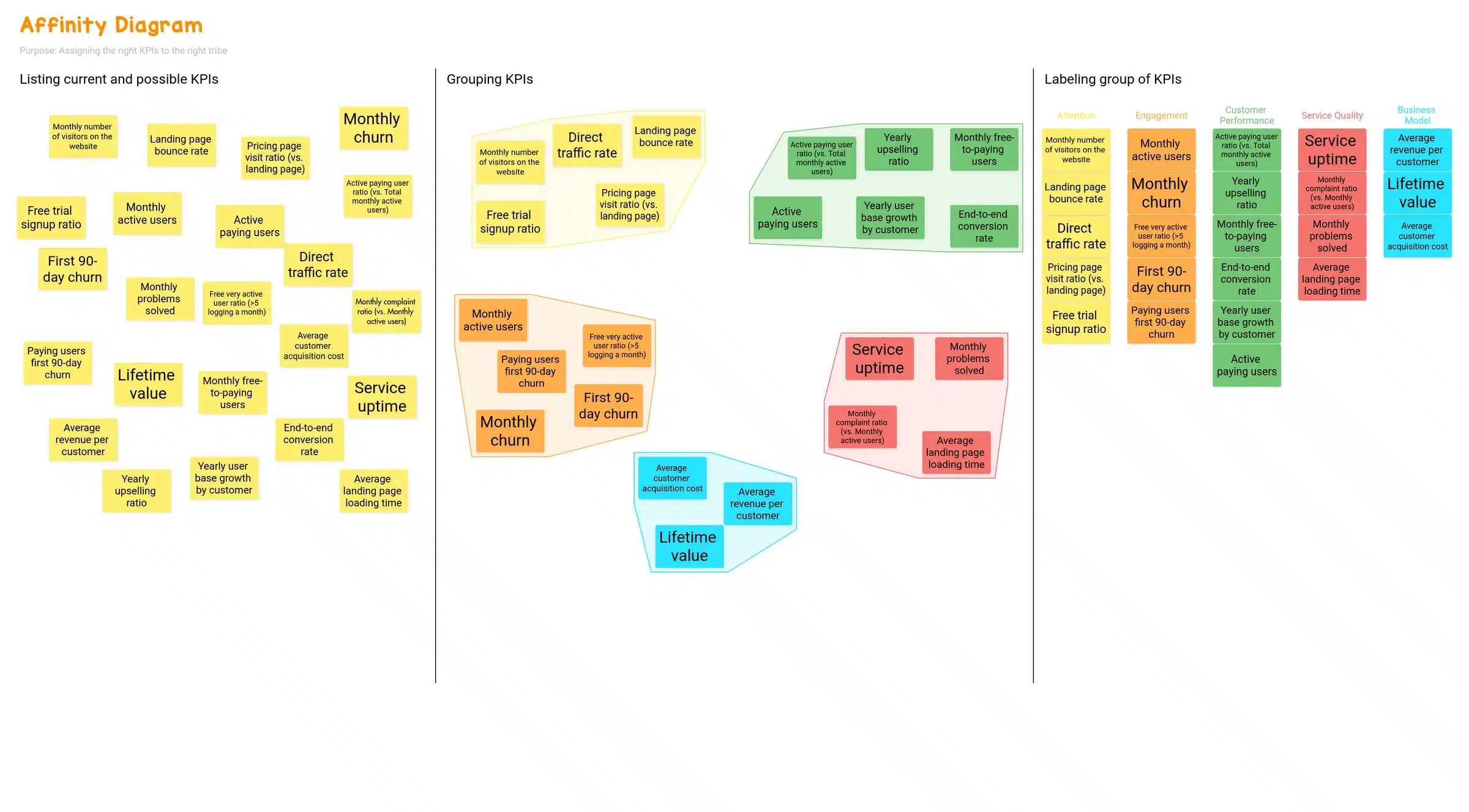

Affinity diagrams

Source: Lucidchart

If you have complex information you need to specify and categorise, Affinity diagrams, or affinity maps, are for you.

As a product manager, you will receive large amounts of customer feedback and stakeholder input and observe complex research findings. That’s why you can use the affinity diagram to make your and your team members’ work easier.

To organise information using the diagram, use sticky notes or a template in which you can easily write data. Then, group each data set based on similarities, patterns, and common themes.

After categorising all your data, label each according to the similarities you used in organising them. As you do so, remember to use short labels so your team can understand them easily. After making the affinity diagram, you can then analyse and evaluate all the information you organised.

Tree diagrams

Source: geeksforgeek.org

A tree diagram, or tree map diagram, is shaped like a tree. Data are categorised into groups and arranged according to their hierarchy and relationships. Most tree diagrams include rectangles, squares, or other shapes that are nested within each other.

This is called a tree diagram because the data are branched according to their relationship. You can use this tool to arrange product information and its correlations for easier understanding within your team.

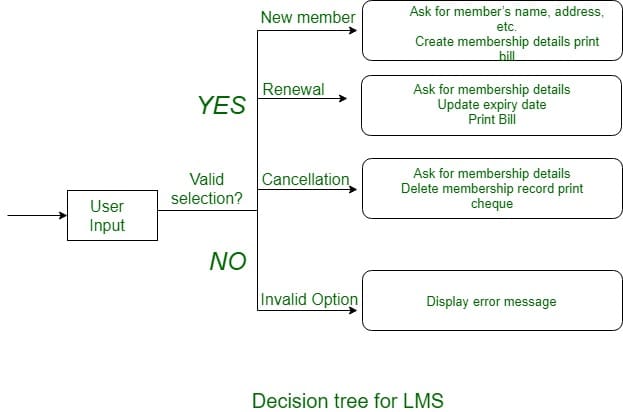

Matrix diagrams

Source: Researchgate

A matrix diagram is a tool that compares several groups or elements within one group. It shows how elements on the row and column relate to each other using the cells between.

You can use this diagram as a product manager to determine the strengths, weaknesses, and associations between variables. Additionally, you can analyse data, concepts, and materials using this.

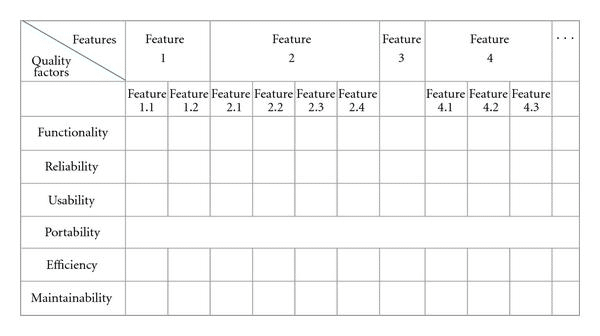

Interrelationship diagraphs

Source: Researchgate

The interrelationship diagram, or relationship diagram, helps find what causes specific problems by breaking down your issues’ relationships. To make this diagram, list the problems you’re facing first. Then, identify whether each of them is the cause or the effect.

Then, put arrows from the causes pointing to their effects. After determining which issue most arrows come from, this is probably the root cause of your problem. You can use this during the quality function deployment if you encounter several issues with your team.

Examples of successful implementation of Quality Function Deployment Process

Different brands and businesses around the world use quality function deployment. That is why it’s recommended for product managers and business professionals to use.

When using it, there are different ways that you can see whether you’ve successfully implemented the QFD. Here are some examples:

Exceed customer expectations

The quality function deployment’s primary focus is to cater to the customer’s preferences. Customer feedback is essential after you have released or upgraded your new product. If this feedback shows that your customer satisfaction rating has increased, you used the quality function deployment well.

Ford Motor Company is the best example of using the QFD to enhance customer satisfaction. The quality function deployment has been vital for them to compete against the global competition in the 1980s.

In addition, they have just launched the Ford Model e where they create different software for cars like BlueCruise for driving assistance. Ford now offers digital products where customers are put first. Design products customers need, which in itself is QFD at work.

The QFD helps you list all the necessary specifications and features you can include in your product to help customers. You have efficiently used the quality function deployment if you can ensure that your product addresses essential customer demands.

Design products customers need

The QFD helps you list all the necessary specifications and features you can include in your product to help customers.

Microsoft is another leading software company that uses quality function development to meet customer needs. Because they provide software services, they need to offer user-friendly features. And so, Microsoft has utilised the QFD to ensure their product’s features can be used easily. Additionally, this has also ensured a more reliable operating system for users.

Reduce human resources needed in the design process

Studies have shown that 52.7% of software development projects exceed the estimated budget because of errors during development. That’s why using the QFD is essential. It allows your software developers to know which specifications or features your next project should have.

Using the QFD, you reduce the changes needed for your software because you have already communicated what your product needs. Doing so results in lower development costs.

IBM, one of the biggest technology corporations developing software products, has efficiently used QFD to reduce costs. Because IBM thoroughly understands their customer’s preferences, they can market their products quickly. Because of this, development and production costs have been reduced and quickened while profits continue to rise.

Benefits of Quality Function Deployment

Quality function deployment is a popular tool among companies for its benefits. Its most important purpose is how it translates customer requirements. But, aside from this, there are several other benefits QFD offers:

Reduce development expenses

Quality control during the design and product development process usually requires a lot of people and developers.

However, if you have successfully implemented the QFD, you would only need a few workers for software design and development. This is because the features and specifications are already decided before the process begins with the help of QFD, so the number of employees that need to work on them is reduced.

Quickens processing time

Without using the QFD, you and your development team would be left with many possibilities for your next product design. In return, this lengthens the processing time to develop a plan. However, you can have a guaranteed list of technical specifications using the quality function deployment. By doing so, the time you spend creating a design is reduced.

Ensure an increase in return on investment

Because the QFD is customer-centred, there’s a big chance that many customers will flock to your product. When this happens, a dramatic increase in your product’s return on investment and profit will be seen.

Ensure an increase in return on investment

Because the QFD is customer-centred, there’s a big chance that many customers will flock to your product. When this happens, a dramatic increase in your product’s return on investment and profit will be seen.

What are the limitations of quality function deployment?

Every product developmental process has limitations, and the quality function deployment is not exempted. One of its limitations is that customers’ preferences aren’t always accurate. For instance, what they say they want may not be how they feel.

Moreover, the QFD doesn’t capture other essential points to consider when developing a product. Its limitations include not considering the cost, the product’s life cycle, and long-term stability in the market.

Conclusion

The quality function deployment method is critical to meet your customer’s needs. Because customers are always right, the product you manage will have sure buyers.

The QFD has four phases you must take, namely, product planning, product development, process planning, and production planning. Moreover, you also need to create a ‘house of quality’ matrix for it. Doing the necessary steps will generate more profit and allow you to spend less time on the design development process.

Mambo is a gamification platform that ensures engagement and motivation when doing any task. Contact us now!

Download your free

“Gamification Guide”

Get your PDF now and start transforming your approach to digital engagement!

Latest Posts

Machine Learning In Finance: 12 Essential Applications

The impact of machine learning on finance is significant. Thanks to this technology, financial institutions are now equipped to make efficient decisions. Through the analysis of data sets, machine learning […]

How To Create Interactive Compliance Training For Bank Employees

Banking compliance training isn’t just another task. It’s the stage where everything else performs. Banks must navigate a myriad of regulations and laws. After all, this is a trust-driven, high-stakes […]

How Fintech Apps Are Using Gamification To Increase User Engagement

Discover how gamification in fintech is revolutionizing financial engagement, making banking fun & boosting user loyalty.